What puts out good brushes really

Redecker brushes are manufactured, as they have been for decades, primarily from native woods, bristles, hair or vegetable fibres. Different natural materials are used to suit various purposes. Synthetic fibres or plastics are rarely used, only for special requirements.Brush bodies

The body of the brush can be made of different types of domestic woods. For the main part, woods such as beech, oak, pearwood, and ash are used. Depending on the intended future purpose, the woods are either processed in an untreated state, or oiled, or waxed.

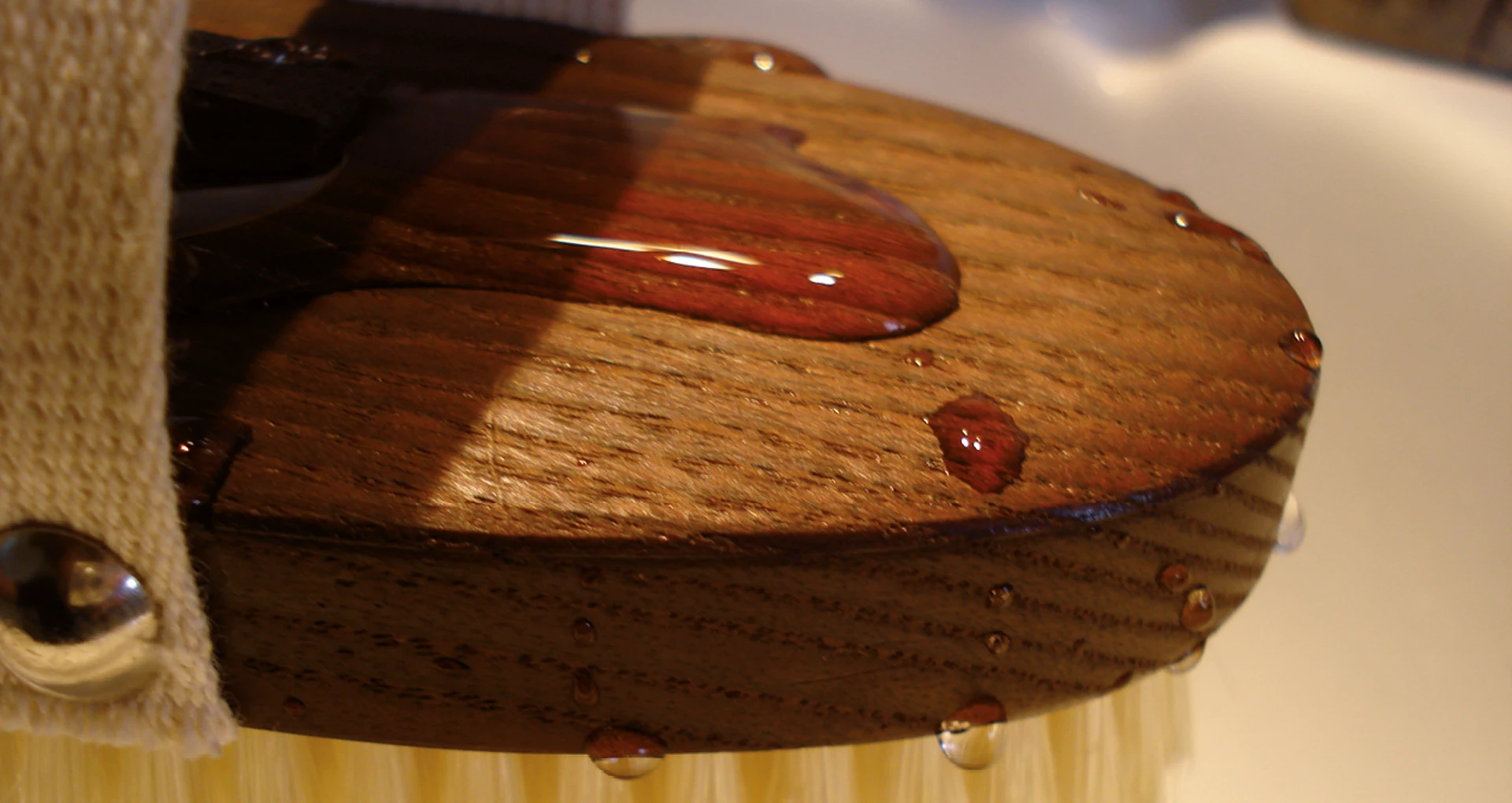

The olive tree grows very slowly and because of this, the wood is very hard. The high oil content also makes it water-repellant, so that olivewood is ideal for use in damp environments.

Thermowood: The molecular structure of wood is altered in a kind of “baking” process at high temperature. The wood sugar is caramelized and the pores are closed. Exposure to heat gives the wood a fine, dark color. Wood processed in this way is called thermowood. It absorbs little or no water and is thus practically insensitive to moisture. It is ideal for all products used in areas where wood is exposed to high moisture levels – from baths to saunas.

The bristles

This is what we call the plant fibres and animal hair that make up the functional part of our brush.

Each type of material used for the bristle portion, or „stocking“ of the brush,

is cleaned, boiled, and combed in a process spanning several steps. We call this treatment ‘finishing.‘

Depending on the application, we use the following materials:

Bristles from animal hair

The ‘hair’ from the domestic pig or the wild boar is called bristles. Bristles are significantly thicker and, therefore; harder at the root than at the tip. Depending on the use, hard or soft brushes can be made depending on whether the lower or upper part of the bristles is used.

Horse hair is a significant material for the brush maker. Hairs from the tail and the mane are used. The strong hair from the horse’s tail is very suitable for the manufacturing of brushes used for cleaning cobwebs, brooms, and for hand brushes. The soft hair from the mane is ideal, among other things, for shoe polishing brushes.

For our products made of split horsehair the hair is split at each end in a mechanical process. This makes them much softer and more flexible and thus ideal for collecting even the finest dust.

The classic bristle for shaving brushes is badger hair. It has rounded tips so it does not irritate or damage the sensitive skin on the face. Its fineness and density ensure a firm, substantial foam. Only the top quality crest hair from the badger’s back is used in our brushes.

The hair of the Chinese long-haired goat is by far the softest material in our brushes. Its very fine and dense hair is used in dusting brushes, cosmetic brushes, and also hairbrushes for babies.

The ostrich feather …

… is the queen of feather dusters. Because the individual feathers actually consist of a structure of numerous small feathers, they don’t simply “wipe” dust away but bind it effectively. Ostrich-feather dusters are especially light and thus ideal for dusting glass surfaces, fragile objects, or smaller pieces that tend to topple over easily. Connoisseurs appreciate their delicate softness as well as their thorough dusting power. Based on the season, the feathers of the ostriches may be larger or smaller, thicker or thinner, lighter or darker. We have no influence over these natural characteristics. For this reason, each feather duster will vary – however, this is what always makes it unique. To guarantee a consistent quality standard; however, the feathers used in binding each feather duster are always kept at the same total weight.

Bristles material made from plant fibres

Tampico fibre is obtained from the leaf ribs of a type of agave which grows on the high plains of Mexico. It has a high degree of shape retention and is used for scrubbing brushes, washing brushes, and anywhere high heat resistance is required.

Palmyra fibre comes from the leaf ribs of palmyra palms which are found in India and Sri Lanka. The core from the stem of this palm provides the starch-containing foodstuff, sago. Palmyra fibre is, like all plant fibres, water-resistant and is used mainly for street-sweeping brooms. However, it is usually blended with other plant fibres to make union fibre, a mixture which is used above all for vegetable scrubbing brushes, mops, and scrubbers because of its hardness and resilience.

Arenga is obtained from the leaf fibres of the Asian sugar palm. Its natural color is dark grey to black. Arenga is finer and softer than other palm fibres, but is nevertheless tough and elastic. Thanks to its lack of sensitivity to wetness, it is ideal for brushes for outdoor use.

Coco is obtained from the fruit of the coconut palm. The fibres lie between the external leathery shell and the actual coconut. They can grow up to 30 cm in length, and are used as bristles for brooms, brushes, and hand brushes. As braided cords, coconut fibres are also made into mats.

Sisal derives from the leaf fibres of the Mexican sisal palm. Its resistance makes it ideal for the manufacturing of mats and massage gloves. Usually it is not used for the bristles of brushes.

The name ‚rice straw‘ is somewhat misleading, as the plant from which it is obtained has nothing to do with rice. ‘Rice straw’ comes from sorghum, a type of cereal which is native to an area from the sub-tropics to the Balkans. Sorghum straw for the manufacturing of ‘rice straw’ is obtained from the upper part of the entire plant, including the panicle. In Germany, the ‘rice straw broom’ became known in the 1960s thanks to guest workers who emigrated from the Balkan countries.